Secrets of the Wood

Wooden barrels have been used for storing and transporting wine since Roman times. Jugs and glassware were too fragile for this purpose. Leather was also used in the past, but since Charlemagne, the use of animal skin for storing wine was banned for hygienic reasons. This was later (1519) during the reign of Charles V also enshrined in a written law. Coincidentally, it was then discovered that wood and especially oak had a great influence on the flavour development of wine and later of eau-de-vie.

Limousin wood has been known since ancient times for its good qualities for preserving wine. When people came to Charente from these regions to buy salt, transporters took wood along the way to avoid having to drive with an empty cart. This wood was sold as cask wood and sold well, and from the time distillation began, this was the wood used to preserve brandy.

The use of other wood only started around the middle of the 20th century. Delamain mentions only Limousin wood in his 1938 book. He does say that American, Russian and other woods were experimented with, but gave worse results in the final flavour.

American oak gives off a certain bitterness and Russian, German and Austrian oak gives off little tannin, so eau-de-vie in it behaves as if it were in a glass barrel: it does not age.

However, due to a shortage of wood, they had to look for other woodlands, and the Forêt de Tronçais in the Allier department also proved to provide suitable wood. Most of this forest was planted in the 17th century at the behest of Jean-Baptiste Colbert, minister to Louis XIV, who needed wood for building ships to form a powerful naval force. The name is derived from the name for the trees that were planted: Tronce. A Tronce is a sessile oak.

These two areas, the Limousin and the Forêt de Tronçais provide all the oak needed for cognac storage.

In the Forêt de Tronçais, the Quercus Sessilis (syn.: Q. Petraea; Q. Sessifloris; Sessifloris oak) grows with its much finer grain and with lots of vanilla and spicy aromas. In the Limousin, Quercus Robur (syn: Q. Pedunculata or Pedunculata oak or in England English oak and in France French oak). It has a coarser grain and contains relatively more tannin, but not as much as, for example, the American white oak (Quercus Alba).

Oaks in Limousin grow about 2 cm in circumference every year, compared to 2 mm/year in the Forêt de Tronçais. This explains the difference in coarseness of the grain.

Sawing or splitting

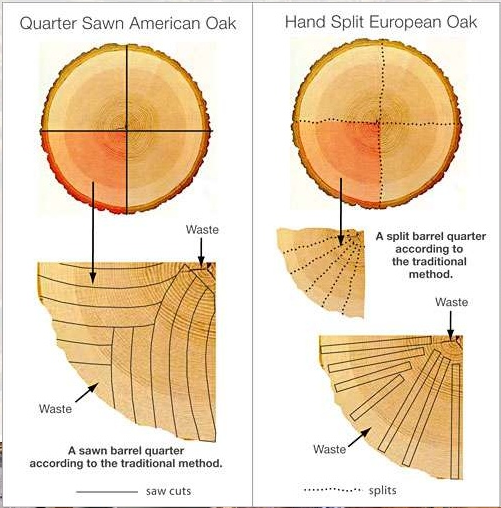

French oak should be cleaved rather than sawn. Sawing destroys the wood cells, making the tannin content too high – and thus the sharpness/bitterness – and also increasing water permeability. As a result, you do lose a lot more wood. More than 80% of the wood cannot be used. If you could saw the wood, like American oak for instance, the yield of usable wood would be twice as high. American oak has more tylose, which has water-sealing properties and can therefore be sawn instead of split. It does give much more wood flavour to the eau-de-vie and sometimes an imposing burnt smell. This makes the flavour more ‘clunky’.

French oak should be cleaved rather than sawn. Sawing destroys the wood cells, making the tannin content too high – and thus the sharpness/bitterness – and also increasing water permeability. As a result, you do lose a lot more wood. More than 80% of the wood cannot be used. If you could saw the wood, like American oak for instance, the yield of usable wood would be twice as high. American oak has more tylose, which has water-sealing properties and can therefore be sawn instead of split. It does give much more wood flavour to the eau-de-vie and sometimes an imposing burnt smell. This makes the flavour more ‘clunky’.

The logs are first cleaved lengthwise into halves, then into quarters, into eighths and finally into exactly the desired size stave. After these merrains, as they are called, are dried, a process that takes two to three years, they are planed into the right shape; the outside convex and the inside concave.

Wood properties

Wood consists of about 5% tannin, 23% lignin and 70% cellulose. French oak wood contains little resin or turpentine, unlike softwood, for example. The alcohol of the spirit extracts tannin and lignin from the wood by dissolving them in the alcohol.

The main aromatic substances in the wood are: eugenol, which provides the spicy aromas and clove scent; vanilla for the sweet taste of vanilla and sugar glaze; and the whisky lactones (so called because they were first identified in whisky) that give aromas of toasted coconut, mushrooms, straw and celery. Over many years, these three flavourings are responsible for the so distinctive rancio.

The vanilla (flavour) comes from the lignin. Vanilla is a phenolic aldehyde. Lignin is a complex polymer of aromatic alcohol groups. Lignin is abundant in wood (lignum means wood) and is one of the most abundant organic polymers on earth. In wood, it is found in the cell walls where it fills the space between the cellulose, hemicellulose and pectin components. Lignin is a raw material for the production of synthetic vanilla.

Eugenol is found in many plants, but particularly abundant in cloves. It is a pale yellow viscous liquid that gives clove its specific aroma. Eugenol was formerly used to produce synthetic vanilla.

Whisky lactone, a cyclic ester, has aromas of coconut, celery and fresh wood. It was first identified in 1970. This lactone is extracted from the wood by the alcohol.

The Limousin wood gives off more tannins and makes for better-balanced cognacs. The different flavour components are brought into harmony, so to speak. The Tronçais wood gives off less tannin but has more aromatic components such as eugenol and methyloctolactone, giving more finesse (delicacy and complexity) to the cognac.

Young wood naturally gives off much more tannin than already used wood. An often used practice is to use new wood only for Fins bois or Bons bois eau-de-vie, but not yet for Petite and Grande champagne. After a year, it can then be used for Petite champagne and again a year later for Grande champagne. Many variations on this are of course possible.

The oak thus has three functions:

1. watertightness allowing it to be a storage vessel for the eau-de-vie;

2. permeability allowing oxidation processes to occur;

3. supplier of aromatic substances and tannin to the eau-de-vie.

Some more can be said about water tightness and air permeability. This is because there is evaporation of water and/or alcohol from the vessel. In humid environments, relatively more alcohol will evaporate than water and in dry environments relatively more water will evaporate.

Air permeability is not direct. It is not the case that air flows freely through the wood from the inside to the outside and vice versa. So the oxidation that occurs is an indirect process involving all kinds of chemical processes in the wood.

Comments

Wood — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>